Meet the Papercast CMS Layout Catalogue: A must have resource for sharing visually impactful passenger information

We’re excited to tell you about the Papercast Content Management System (CMS) Layout Catalogue, an…

If you asked us 5 years ago what we would be doing in 5 years’ time – in fact, if you asked us 1 year ago – we still never would have predicted how this last year has played out.

We don’t need to lay out the details, most of us are living with restrictions in one form or another. But one of the most significant – and the most relevant to this article – is the travel restrictions. Not only has this had a direct (and profound) impact on our sector, but it has also changed how we go about our day to day business.

We serve a global customer base from our London head office, with development and manufacturing in Slovenia. It is not uncommon for new customers to visit our production facilities so they can see what goes into creating our innovative e-paper displays.

Restrictions on global travel have put these visits on hold.

We planned to produce a video, but unfortunately, we have not been able to give external visitors access to our production facilities. Our priority is to both keep our team safe and keep production at full capacity.

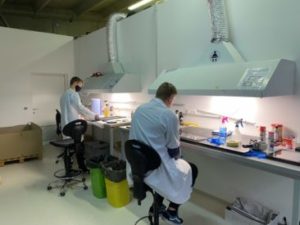

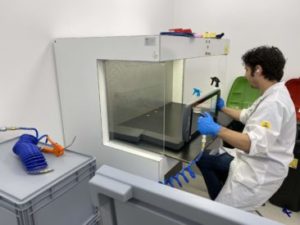

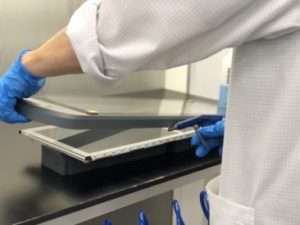

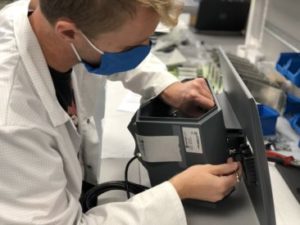

And so here we are, taking you on a different type of journey. One with a photo story put together by our Production Planning Manager, Nina Čebin. Here she will walk you through the Papercast production process, so you can see what goes into assembling our e-paper displays and solar power modules to the highest standards.

Preparing the front housing frame and installing the speakers

Preparing the back housing frame and installing the connectors

Preparing the display module and installing the LED lights

Glazing the front housing frame

Optical bonding quality control

Installing the display module into the front housing frame

Attaching the display module, sealing the frame with silicone tube and glass with silicone glue

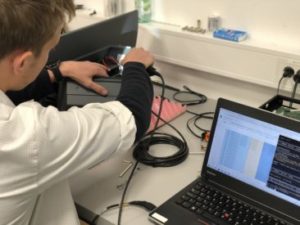

Installing the electronics, and connecting the cables and processing boards

Scanning serial numbers, control procedure, installation of test SIM and SD cards

24h burn-in test

Removing the test SIM card, securing the back housing to complete the display, detailed cleaning and applying the protective screen foil, generating QA report

Packing

Assembling the solar panel onto the solar frame

Installing the BMS processing board on the BMS holder

Connecting the battery box with the solar frame and panel

Testing

Ready to go

We hope you have enjoyed this guided tour through our manufacturing environment. Now you can see what it takes to produce Papercast’s market leading e-paper displays and solar modules. If you have any questions or would like to see our e-paper displays in action, please contact us or book a demo.

We’re excited to tell you about the Papercast Content Management System (CMS) Layout Catalogue, an…

The REACT Trigger System is now available on Papercast displays We’re excited to share that…